Spring Environmental assists facilities in obtaining and maintaining air permits. Services include evaluating and calculating facility emissions, selecting appropriate process and control equipment, and performing or coordinating monitoring.

Engineering

Under the EPA, State and Local New Source Review rules (“NSR”), best available control technologies (BACT) are required for construction and modification of specified stationary sources. Spring Environmental assists with selection and evaluation of pollution control technologies and equipment.

Project Examples:

- Pacific Northwest Farmers Cooperative operates a grain terminal near Rosalia, Washington. The facility added four additional grain storage piles, and required an evaluation of technologies to control particulate emissions. Spring Environmental analyzed the sources of emissions, reviewed available control technology, evaluated the technical specifications and economic feasibility of the options available, and made recommendations for emission controls.

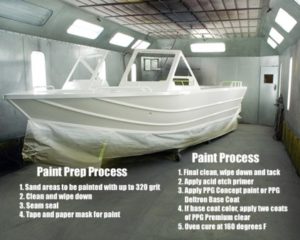

Hewes Marine Company has manufactured Hewescraft all-welded, heavy gauge, aluminum boats in dozens of different option configurations and sizes ranging from 16’ to 26’ in Colville, WA since 1948. Modifications to the facility and processing required several specific sources at the facility to be evaluated for emission control technology, including plasma cutting, welding, and painting. Spring Environmental analyzed the sources of emissions; reviewed available control technology, specifications and costs from various pollution control suppliers; evaluated technical and economic feasibility of the options available; and made recommendations for emission controls.

Hewes Marine Company has manufactured Hewescraft all-welded, heavy gauge, aluminum boats in dozens of different option configurations and sizes ranging from 16’ to 26’ in Colville, WA since 1948. Modifications to the facility and processing required several specific sources at the facility to be evaluated for emission control technology, including plasma cutting, welding, and painting. Spring Environmental analyzed the sources of emissions; reviewed available control technology, specifications and costs from various pollution control suppliers; evaluated technical and economic feasibility of the options available; and made recommendations for emission controls.

Permitting

Depending on the location of the source, the regulatory jurisdiction and the total amount of emissions, different air permits are required.

- New Source Review (NSR) permits may be referred to as Notices of Construction (NOC) in Washington State, Permit to Construct (PTC) in Idaho, General Orders (GP or GO) on Tribal Lands and in Washington, and Permit by Rule (PBR) in Idaho. NSR requires that stationary sources of air pollution get permits before they begin construction. The permits detail what construction is allowed, what emission limits must be met, how the source must be operated, and what records must be kept. These permits normally do not expire and only require modification in the source changes, emissions increase, or emissions change.

- Title V Air Operating Permits are known as AOPs in Washington State, Montana and on Tribal Lands and Tier 1 permits in Idaho. Title V applies to “major sources” of air pollution based on facility wide potential to emit. Air Operating Permits (AOPs) encompass all regulatory requirements applicable to the facility including emission limits, monitoring, reporting, and record keeping. These permits normally require renewal every 5 years and are subject to review by both the local/state jurisdiction and EPA.

- Synthetic Minor Permits are also known as Tier II permits in Idaho. A Synthetic Minor Operating Permit is a legally binding permit allowing a facility to lessen the extensive requirements for a major source facility by incorporating terms and conditions that lower the facility’s potential to emit air contaminants to below the major source thresholds. These permits may have a 5-year term (Idaho) or have no expiration (Washington, EPA).

Spring Environmental has extensive experience assisting clients with their permitting needs, including air quality modeling, emission calculations, Best Available Control Technology (BACT) analysis, determination of applicable regulatory requirements and preparation of permit applications.

Project Examples:

Renaissance Marine Group is an aluminum boat manufacturing company located in Washington. Spring Environmental prepared an Notice of Construction (NOC) air permit application to relocate the operations to a new location. The permitting process included identifying and quantifying emissions from a paint booth, natural gas combustion, and welding operations; preparing a BACT analysis; performing an air modeling assessment; and compiling a State Environmental Policy Act (SEPA) checklist.

Renaissance Marine Group is an aluminum boat manufacturing company located in Washington. Spring Environmental prepared an Notice of Construction (NOC) air permit application to relocate the operations to a new location. The permitting process included identifying and quantifying emissions from a paint booth, natural gas combustion, and welding operations; preparing a BACT analysis; performing an air modeling assessment; and compiling a State Environmental Policy Act (SEPA) checklist.- Spunstrand is a fiberglass manufacturing company located in Idaho. Spring Environmental prepared a Tier 1 application to renew their current Title V Air Operating Permit. This renewal application process included an emissions inventory, a regulatory applicability analysis, a compliance plan, and compliance certifications.

Central Pre-Mix is a sand and gravel, concrete, and asphalt company with portable and stationary plants throughout the Northwest. Spring Environmental has assisted with permitting multiple plants in Washington, Idaho, and on Tribal Lands. Services provided included identifying and quantifying emissions, performing air modeling assessments, ascertaining Best Available Control Technology (BACT) analysis, compiling permit applications, identifying endangered species and historic properties, and negotiating with regulatory agencies.

Central Pre-Mix is a sand and gravel, concrete, and asphalt company with portable and stationary plants throughout the Northwest. Spring Environmental has assisted with permitting multiple plants in Washington, Idaho, and on Tribal Lands. Services provided included identifying and quantifying emissions, performing air modeling assessments, ascertaining Best Available Control Technology (BACT) analysis, compiling permit applications, identifying endangered species and historic properties, and negotiating with regulatory agencies.- Yakima Valley Memorial Hospital contracted Spring Environmental to prepare a Tier 2 Notice of Construction (NOC) application for an emergency generator. The application required a health impact assessment which included emission calculations, air dispersion modeling, and an exposure assessment.

Monitoring

Visible Emissions / Opacity Monitoring (EPA Methods 9 and 22)

Visible Emissions Monitoring may be required only once, or on an ongoing basis according to a facility’s air permit requirements. Visible Emissions Training and Certification, known as smoke school, is required by the US Environmental Protection Agency (EPA) in order for an individual to be recognized as a qualified observer of stationary emissions sources. Spring Environmental maintains multiple staff trained, certified and experienced in Visible Emissions or Opacity Monitoring.

Project Examples:

- Agri Beef Cattle operates El Oro Cattle Feeders near Moses Lake, WA and required Visible Emissions Observations (Method 9) in order to collaborate with the Department of Ecology on improving feed processing operations. Spring Environmental performed Method 9 observations for feed hopper loading, and hay grinding operations.

- Easterday Ranches operates a cattle feeding operation near Pasco, WA that required Visible Emissions Observations (Method 9) to determine compliance with their air permit. Spring Environmental performed Method 9 observations for hay barn unloading, bunker loading, and feed mill operations.

- DeAtley Crushing operates six portable rock crushing plants in Idaho and Washington that required Visible Emissions Observations (Method 9) per 40 CFR 60 Subpart OOO and in accordance with the respective air permits. Spring Environmental performed Method 9 observations on up to 25 fugitive emissions sources on multiple occasions to determine compliance with the facility’s permit and federal regulations.

Pinnacle Crushing operated two rock crushing plants in Yakima, WA that required Visible Emissions Observations (Method 9) per 40 CFR 60 Subpart OOO under the YRCAA air permit. Spring Environmental performed Method 9 observations on up to 15 fugitive emissions sources to determine compliance with the facility’s permit and federal regulations.

Pinnacle Crushing operated two rock crushing plants in Yakima, WA that required Visible Emissions Observations (Method 9) per 40 CFR 60 Subpart OOO under the YRCAA air permit. Spring Environmental performed Method 9 observations on up to 15 fugitive emissions sources to determine compliance with the facility’s permit and federal regulations.- Spring Environmental works with several lumber mills in Idaho and Washington that operate hog fuel boilers to produce steam for mill operations. These boilers require periodic air emission source testing. Visible emissions observations are often required in concert with the source testing. Spring Environmental coordinates and performs visible emissions monitoring in concert with performance testing on the boilers.

Source Testing

Source testing may be required as part of a facility’s permit to construct or air operating permit, as a compliance mitigation requirement, or used to verify site specific emission factors. Testing includes the characterization of pollutants being emitted from a specific source, typically using standard methods outlined by the Environmental Protection Agency under 40 CFR 60 Appendix A. Spring Environmental can provide source testing services including the development of a source test plan, filing intent-to-test notifications, coordination and design of testing, and evaluating and reporting source test results.

Project Examples:

- Stimson Lumber Company operates several lumber mills throughout the Northwest. In order to fulfill an Idaho site’s permit requirements, Spring Environmental coordinated source testing on the lumber mill’s hog fuel boiler using EPA method 201A/202. This included review and submittal of the source test plan, on-site coordination during testing, and review and submittal of the final report to the regulatory agency.

- Holy Family Hospital is located in Spokane, Washington and operates an ethylene oxide sterilizer for on-site sterilization of surgical equipment. The sterilizer is permitted under the Spokane Regional Clean Air Agency and requires Holy Family Hospital to perform a source test using OSHA Method 1010 to verify the control efficiency of the ethylene oxide disposer. Spring Environmental prepared and submitted source test plans and notifications to the regulatory agency, performed the source testing, and analyzed and submitted the reports.